FILTRATION SOLUTION & SAFETY

- Patented extractable free filter cartridges are NSF/ ANSI Standard 61.

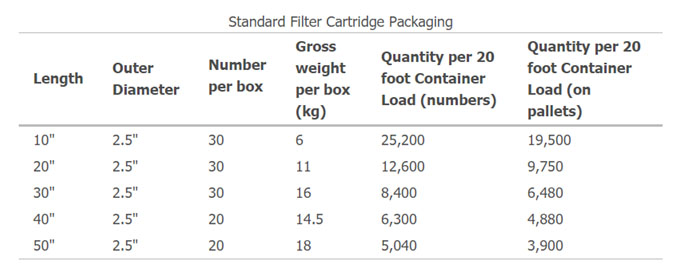

- Lengths from 10 inches to 72 inches and up to 6 inch diameter.

- Suitable for use in applications like RO Pre-treatment (SDI Reduction), Sea Water Desalination, Drinking Water and Beverage, processing, Gas Purification, Electronics and Electroplating, Photographic Solutions, etc.

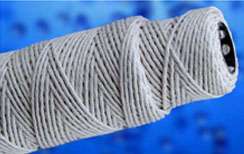

Polypropylene Cartridges

Free from any extractable and contain no lubricants, wetting agents, emulsifiers, anti-oxidants or anti-static agents, etc.

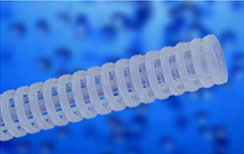

Coalescer Cartridges

Reduce cost of filtration with enhanced performance, and is ideal for condensate removal and oil adsorption in both liquid/liquid and liquid/gas applications.Applications include removal of aerosols, condensates and particulate contaminants from natural gas streams.

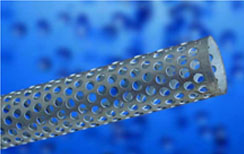

Reverse Osmosis Cartridges

Filters for reverse Osmosis Plants are effective and efficient for removal of silt, sand, rust and other suspended particles from RO feed water.

END ADAPTORS

Polypropylene closed end cap

Stepped End Configurations

Reusable Knife-Edged Seal End Cap

Fin End Cap

Polypropylene Molded Spring

Polypropylene Molded Adapter with 222 O-rings

EXTENDED CORES

Pure Polypropylene Extended Core

Pure Polypropylene Tapered Extended Core

Stainless Steel 316L Tapered Extended Core

FILTER CORES

Polypropylene

Economical Choice for most application

Stainless Steel

For higher temperature, oil, acids, and other corrosive fluids, as well as food and beverages

Galvanized Carbon Steel

General purpose core for oils, solvent, paints and other non- food applicationFILTER CARTRIDGES FOR REVERSE OSMOSIS PLANTS

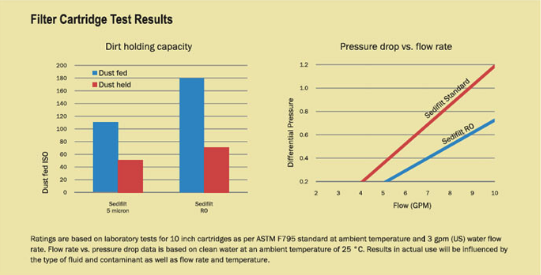

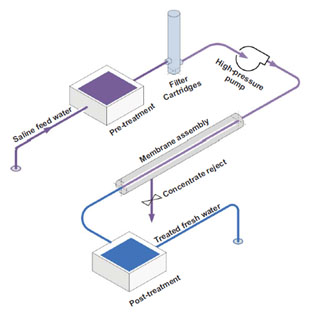

Cartridge filtration is the final safety step to protect the membranes and high pressure pump from any suspended particles.

RO system manufacture recommend final pre-filtration before the Pressure pump and membrane with filter cartridges of <= 5 micron. Properly selected cartridge filtration as the final safety step has a number of benefits:

- Protects membranes and high pressure pump

- Removes any remaining suspended particles

- Reduces membrane cleaning requirements

- Reduces risk of fouling

- Removes residual flocks and particles after multi-media

- Provides useful information regarding fouling risks and cleaning requirements (by regular inspections of used cartridges)

- Indicates extent of fouling with increase in pressure drop. For example, if the differential pressure across the filter increases rapidly, it is an indication of possible problems in the raw water supply or in the pretreatment process

- Provides short-term protection for the membranes while corrective action is taking place

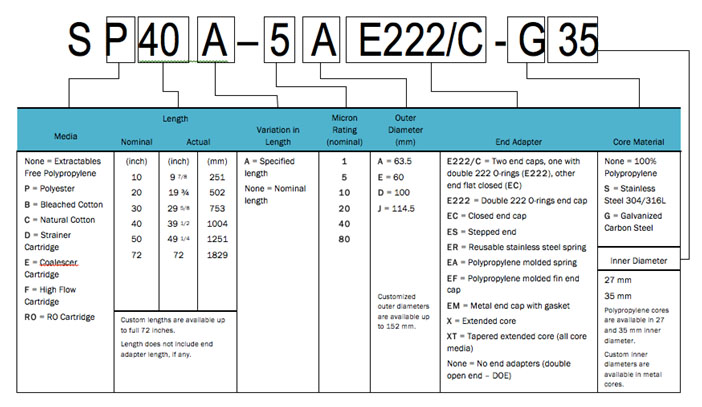

ORDERING INFORMATION

Comfilt cartridges can also be made to order in desired sizes (inner diameter, outer diameter, and lengths), filter media and core material.

PRODUCT CODE GUIDE

We also provide solution from small, medium to large size turnkey filtration systems STP’s and ETP’s

COMMITMENT IS OUR IDENTITY. COMMITMENT FOR WHAT WE COMMIT